Welcome to Shanghai Bosen Environmental Protection Technology Co., Ltd.

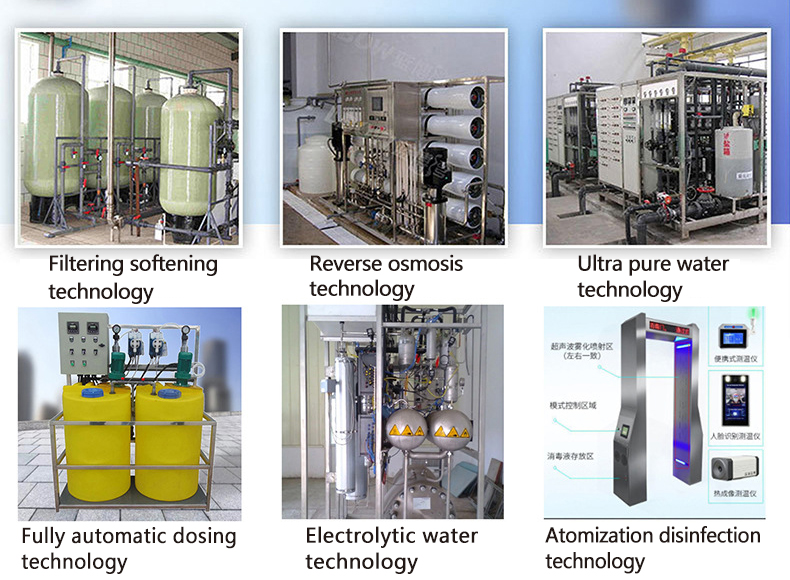

Professional equipment company focusing on water treatment equipment and integrating R&D, manufacturing, sales and service

+852 5534 9894

+86 177 175 91248

Over the past 5 years, we have solved water problems for tens of thousands of enterprises

产品展示

products