- Home

- Product

- Seawater desalination equipment

- EDI ultrapure water equipment

- Laboratory ultrapure water machine

- Ultrafiltration equipment

- Sewage treatment equipment

- Container integrated water purification equipment

- Double-stage reverse osmosis equipment

- Pure water equipment

- Single-stage reverse osmosis equipment

- Medical purified water equipment

- Hospital pure water equipment

- Ultrapure water equipment

- Recycled water reuse equipment

- Commercial pure water machine

- About

- Case

- News

- Contact

Over the past 5 years, we have solved water problems for tens of thousands of enterprises

产品展示

products

- Sewage treatment equipment

- Laboratory ultrapure water machine

- Ultrapure water equipment

- EDI ultrapure water equipment

- Medical purified water equipment

- Hospital pure water equipment

- Pure water equipment

- Single-stage reverse osmosis equipment

- Double-stage reverse osmosis equipment

- Seawater desalination equipment

- Ultrafiltration equipment

- Container integrated water purification equipment

- Recycled water reuse equipment

- Commercial pure water machine

Laboratory GMP purified water equipment, dual-stage reverse osmosis EDI purified water equipment, inspection department Purified water machine

Equipment used to produce purified water to meet medical needs. The entire system is constructed entirely of stainless steel, and sterilization equipment is installed before each water point. Using reverse osmosis, EDI, and other processes, a comprehensive high-purity water treatment process is designed to meet the purified water production and large-volume infusion requirements of pharmaceutical factories and hospitals.

Equipment used to produce purified water to meet medical needs. The entire system is constructed entirely of stainless steel, and sterilization equipment is installed before each water point. Using reverse osmosis, EDI, and other processes, a comprehensive high-purity water treatment process is designed to meet the purified water production and large-volume infusion requirements of pharmaceutical factories and hospitals.

Introduction to GMP Purified Water

Equipment used to produce purified water to meet medical needs. The entire system is constructed entirely of stainless steel, and sterilization equipment is required before each water point. Using processes such as reverse osmosis and EDI, a comprehensive high-purity water treatment process is designed to meet the purified water production and large-volume infusion requirements of pharmaceutical factories and hospitals.

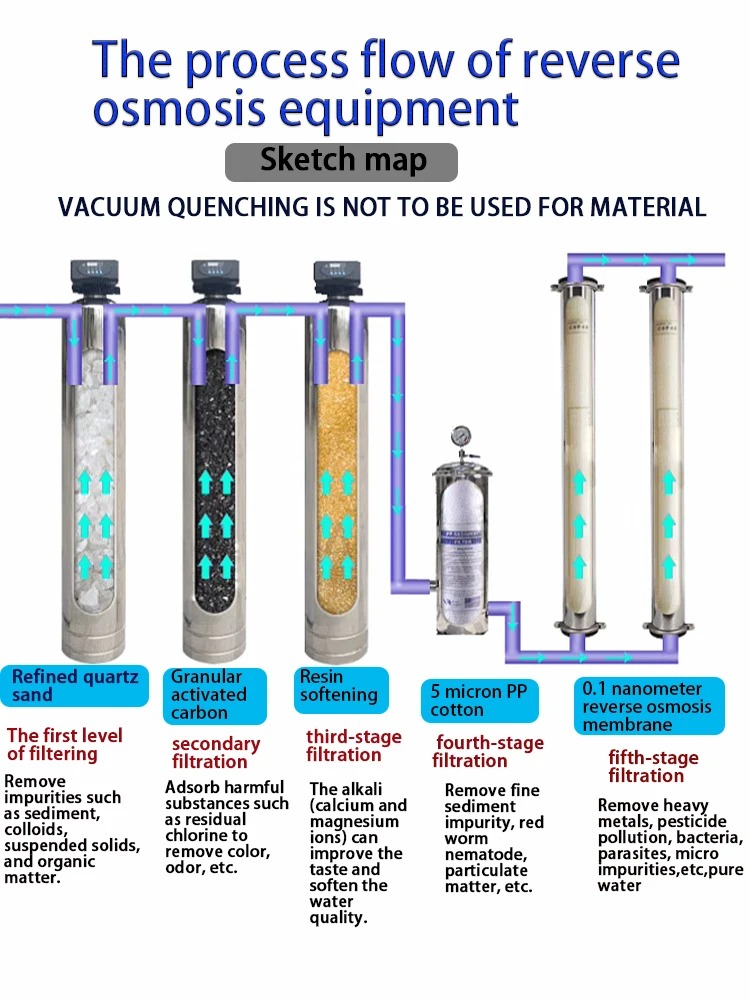

Purified Water Process Flow

Raw water → Raw water tank → Raw water booster pump → Multi-media filter → Activated carbon filter → Cationic water softener → Precision filter → First-stage booster pump → First-stage reverse osmosis → Intermediate water tank → Second-stage booster pump → Second-stage reverse osmosis → Purified water storage tank → Purified water booster pump → Ultraviolet sterilizer → Microporous filter → Water point

Water used in the production of biological preparations, pharmaceuticals, medical devices, and cosmetics.

Solvents or laboratory water for preparing pharmaceutical preparations; solvents or diluents for oral or topical preparations; cleaning water for instruments used in non-sterile preparations; solvents for extracting medicinal herbs used in non-sterile preparations; solvents or diluents for preparing injectables; cleaning water for injection containers; cleaning water for medical devices; water for cosmetics production; and water for disinfectant wipes production. Water effluent standards comply with relevant national regulations.

Purification water equipment parameters

Water inlet requirements | Municipal tap water |

Water quality | The effluent water quality : conductivity (25°C water temperature) <5.1us/cm, total organic carbon <0.5mg/L |

Water production | 2000L/H, (25℃ water temperature) |

Recovery rate | 60-65% |

Raw water inlet water pressure | 0.2-0.4MPa |

Applicable water temperature | 10-40℃ |

power | 4.5KW |

Suitable power supply | AC380V 50HZ |

External dimensions | 1400*800m*1500(Length*Width*H) |

Interface size | Water inlet: 32 Wastewater outlet: 25 Water purification outlet: 25 |

Purified water equipment must meet certain requirements:

1. The structural design of GMP purified water equipment should be simple, reliable, and easy to assemble and disassemble.

2. To facilitate assembly, disassembly, replacement, and cleaning of parts, actuator design should utilize standardized, universal, and systematic components whenever possible.

3. The interior and exterior surfaces of the equipment must be smooth, flat, and free of dead corners, ensuring easy cleaning and sterilization. Parts should be chrome-plated or treated to prevent corrosion and rust. Avoid using paint on the exterior of the equipment to prevent peeling.

4. GMP purified water equipment should be constructed of low-carbon stainless steel or other materials proven to be non-contaminating. GMP purified water equipment should be cleaned regularly, and the cleaning effectiveness verified.

5. Materials that come into contact with water for injection must be high-quality low-carbon stainless steel (such as 316L stainless steel) or other materials proven to be non-contaminating. Equipment used to prepare water for injection should be cleaned regularly, and the cleaning effectiveness verified. 6. Purified water produced by GMP purified water equipment should not be stored for more than 24 hours. Storage tanks should be constructed of stainless steel or other materials proven to be non-toxic, corrosion-resistant, and non-leaking of contaminating ions. Protect the vents with a non-shedding, hydrophobic sterilizing filter. The interior of the reservoir should be smooth, with no dead corners or holes in the pipes or welds. Sensors that display parameters such as liquid level, temperature, and pressure should be used and should not cause stagnant water contamination. The reservoir should be cleaned, disinfected, and sterilized regularly, and the effectiveness of the cleaning and sterilization procedures should be verified.

Application Areas

what app

Address: No. 9655, Tingwei Highway, Jinshan Tinglin Industrial Zone, Shanghai

Mobile phone: +86 17717591248

WhatsApp: +852 5534 9894

Email: bosen7298@gmail.com

- Home

- Product

- Seawater desalination equipment

- EDI ultrapure water equipment

- Laboratory ultrapure water machine

- Ultrafiltration equipment

- Sewage treatment equipment

- Container integrated water purification equipment

- Double-stage reverse osmosis equipment

- Pure water equipment

- Single-stage reverse osmosis equipment

- Medical purified water equipment

- Hospital pure water equipment

- Ultrapure water equipment

- Recycled water reuse equipment

- Commercial pure water machine

- About

- Case

- News

- Contact