- Home

- Product

- Seawater desalination equipment

- EDI ultrapure water equipment

- Laboratory ultrapure water machine

- Ultrafiltration equipment

- Sewage treatment equipment

- Container integrated water purification equipment

- Double-stage reverse osmosis equipment

- Pure water equipment

- Single-stage reverse osmosis equipment

- Medical purified water equipment

- Hospital pure water equipment

- Ultrapure water equipment

- Recycled water reuse equipment

- Commercial pure water machine

- About

- Case

- News

- Contact

Over the past 5 years, we have solved water problems for tens of thousands of enterprises

产品展示

products

- Sewage treatment equipment

- Laboratory ultrapure water machine

- Ultrapure water equipment

- EDI ultrapure water equipment

- Medical purified water equipment

- Hospital pure water equipment

- Pure water equipment

- Single-stage reverse osmosis equipment

- Double-stage reverse osmosis equipment

- Seawater desalination equipment

- Ultrafiltration equipment

- Container integrated water purification equipment

- Recycled water reuse equipment

- Commercial pure water machine

250L/H double-stage reverse osmosis equipment , large-scale industrial water purification treatment equipment , RO water purification equipment , deionizer

250 L/H, double-stage reverse osmosis equipment, suitable for use in various places, pure water commercial, medical industry, direct drinking water treatment, etc., to create clean water quality

250 L/H, double-stage reverse osmosis equipment, suitable for use in various places, pure water commercial, medical industry, direct drinking water treatment, etc., to create clean water quality

250L/H Two stage reverse osmosis equipment

The reverse osmosis equipment passes the raw water through fine filters, granular activated carbon filters, compressed activated carbon filters, etc., and then pressurizes it through a pump, utilizing a pore size of 1/10000 μ The reverse osmosis membrane (RO membrane) of m (equivalent to 1/6000 of the size of Escherichia coli and 1/300 of the size of the virus) converts high concentration water into low concentration water, while isolating all impurities such as industrial pollutants, heavy metals, bacteria, viruses, etc. that have been mixed into the water, in order to meet the prescribed physical and chemical indicators and hygiene standards for drinking, and produce clean to pure water, It is the best choice for the human body to replenish high-quality water in a timely manner. Due to the fact that the water purity produced by RO reverse osmosis technology is currently the highest among all water production technologies mastered by humans, with a cleanliness of almost 100%, therefore, it is widely used in the electronics industry, food and beverage industry, glass manufacturing, new material product cleaning, power industry, electroplating and coating production requirements, etc.

RO system introduetion:

RO system is raw water through precision filter, granular activated carbon filters, activated carbon fiters, compression, and thenthrough the pump pressure, the use of reverse osmosis membrane pore size 1/10000um make a higher concentration of water intclow concentration of water, while the industrial pollutants, heavy metals, bacteria., viruses and other impurities in the water mixedwith a large number of full isolation, to achieve the required physical and chemical indicators for drinking and hygiene standards.outputs to clean pure water is the best choice of body replenish water quality. It is key equipment of pure water plant.

Working process of RO system:

Raw water pump - Mechanical filter - Activated carbon filter - Sodium-on exchanger - Precision filter - Highpressure pump-Reverse osmosis -Ozone sterilizer (uw).

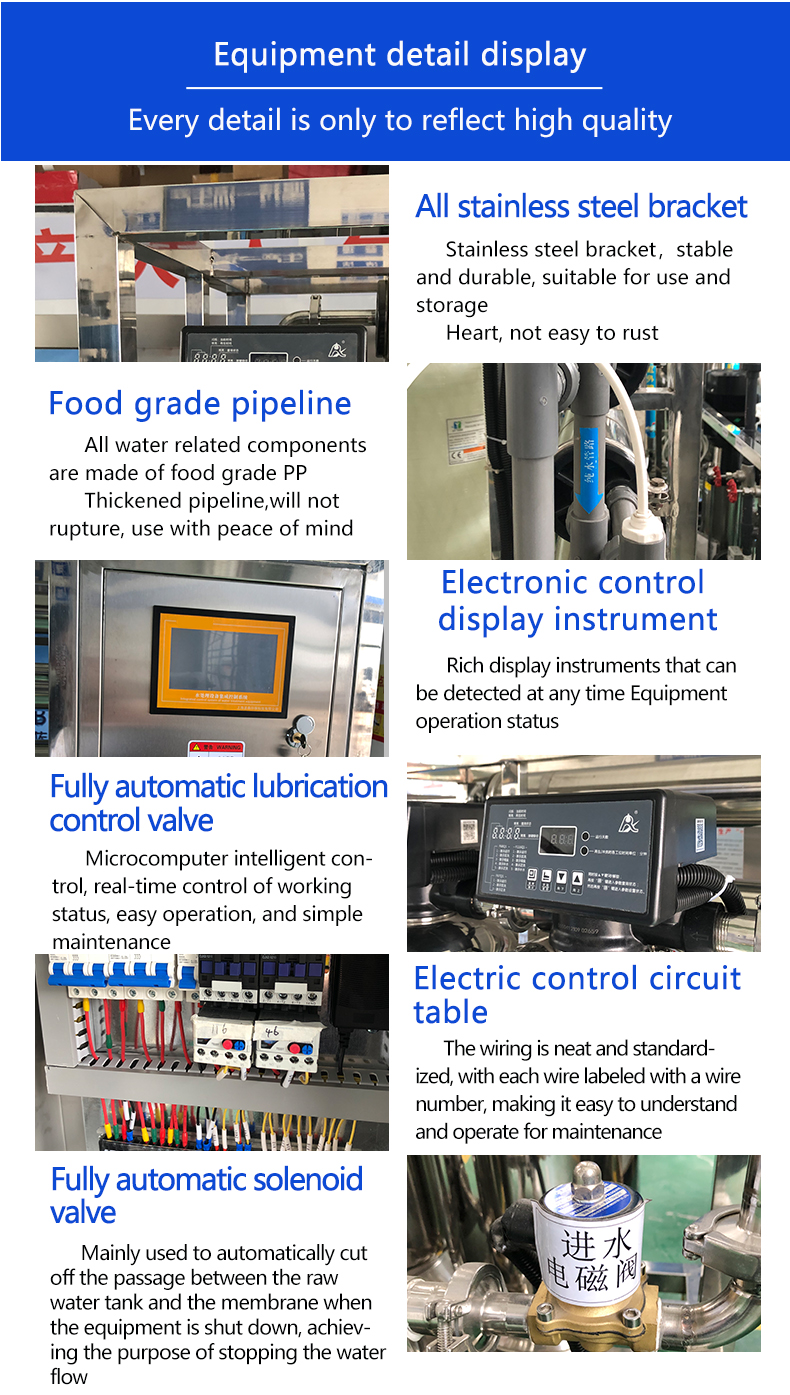

1. Water tank : Storage of tap water, to solve the problem of insuficient tap water pressure and the back booster pumpdue to the impact of insufficient water, reduce the failure rate.

2. Raw water' pump : Equipped with a stainless steel pump, to provide sufficient pressure for subsequent filtration

3. Quar'tz sand filter : Mainly remove the mud, suspended solids and large particles in the tap water.

4. Carbon filter : Mainly remove organic substances, residual chlorine and odor in tap water.

5. WWater softener filter : Mainly remove the calcium and magnesium in tap water, reduce the hardness of water.

6. Security filter : Further filtration, protection of reverse osmosis membrane

7. High pressure pump : Provide enough pressure for reverse osmosis system.

8. Reverse osmosis unit : The core part of pure water equipment, the production of high-purity water

9. Pure water tank : Storage pure water, can change the size of the water tank, after the below process, the water result ispure enough for different application.

What is EDI?

Electrodialysis technology and ion exchangetechnology, through the cation, anion membraneon the choice of positive and negative ionsthrough the role of ion exchange resin on theexchange of ions in the water under the action ofthe electric field to achieve the migration of ionsin the water, wvhich can achieve a deep waterpurification desalination, and through the waterelectrolysis of hydrogen ions and hydroxide ionson the packaging resin for continuousregeneration.

Process flow chart of 250 L/H dual-stage reverse osmosis equipment

Raw water tank - Raw water pump - Quartz sand filtration - activated carbon filtration - resin softening filtration - security filter - - high-pressure pump - secondary reverse osmosis system - secondary reverse osmosis system - pure water tank - ultraviolet sterilization 1 Precision filter - variable frequency water supply pump

250 liters/hour dual-stage reverse osmosis equipment parameters

| Water production | 250L/H, 25℃ water temperature |

| Water inlet requirements | Tap and groundwater, soluble total solid (TDS≤300ppm) |

| Water production standards | Electropositive rate>18.2mQ/cm |

| External dimensions | 1800*700*1760cm (length*width*height), customizable |

| Working water pressure | 0.2-0.4MPa |

| Recovery rate | 85% (can be adjusted according to actual process) |

| power | 3.5KW |

| Control method | Fully automatic (with manual control capability) |

| Suitable power supply | AC380V 50HZ |

| Preprocessing system | (quartz sand, activated carbon, resin softening, precision) filter |

| Reverse osmosis system | First-level reverse osmosis + second-level reverse osmosis |

| EDI system | EDI membrane stacking device, continuous electrostatic desalting |

| Post-processing system | TOC, UV sterilizer, micropore filter |

| How to run | Automatic operation, can work continuously for 24 hours |

The low-concentration side water of the reverse osmosis device will diffuse through the semipermeable membrane to the high-concentration side until dynamic equilibrium is achieved. At this time, the liquid level difference between the two sides of the semipermeable membrane becomes osmotic pressure. When an external pressure is added to the high concentration side, as the pressure increases, water molecules gradually penetrate to the low concentration side. When the applied pressure is greater than the osmotic pressure, the liquid level on the low concentration side will be higher than the liquid level on the high concentration side. This phenomenon is called reverse osmosis

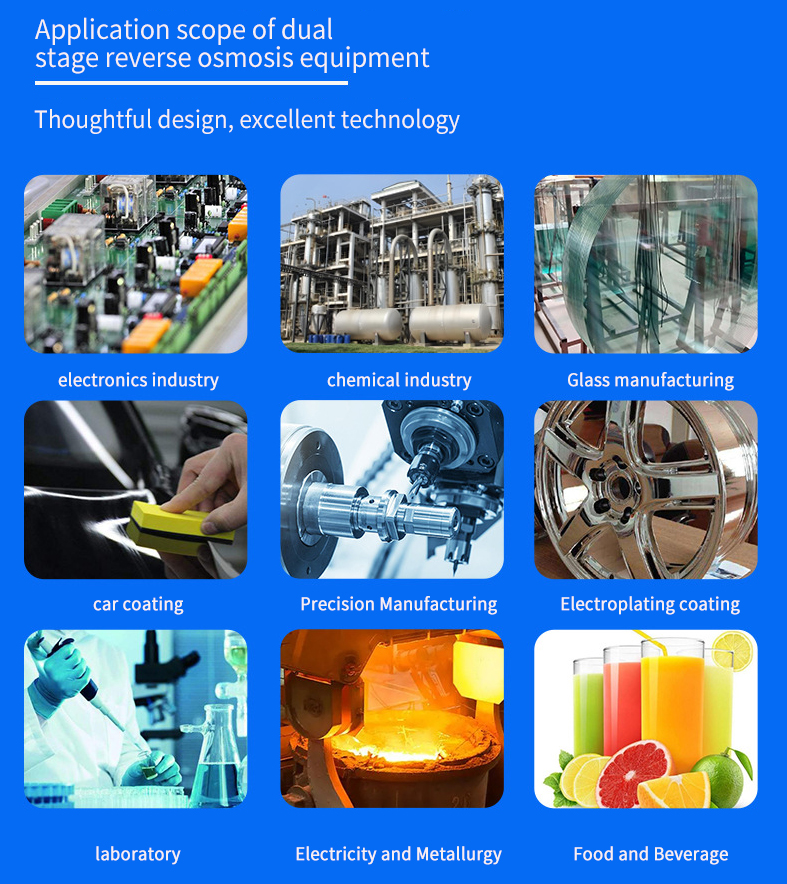

Widely used in the electronics industry, food and beverage industry, glass manufacturing, new material product cleaning, power industry, electroplating and coating production requirements, etc.

what app

Address: No. 9655, Tingwei Highway, Jinshan Tinglin Industrial Zone, Shanghai

Mobile phone: +86 17717591248

WhatsApp: +852 5534 9894

Email: bosen7298@gmail.com

- Home

- Product

- Seawater desalination equipment

- EDI ultrapure water equipment

- Laboratory ultrapure water machine

- Ultrafiltration equipment

- Sewage treatment equipment

- Container integrated water purification equipment

- Double-stage reverse osmosis equipment

- Pure water equipment

- Single-stage reverse osmosis equipment

- Medical purified water equipment

- Hospital pure water equipment

- Ultrapure water equipment

- Recycled water reuse equipment

- Commercial pure water machine

- About

- Case

- News

- Contact