- Home

- Product

- Seawater desalination equipment

- EDI ultrapure water equipment

- Laboratory ultrapure water machine

- Ultrafiltration equipment

- Sewage treatment equipment

- Container integrated water purification equipment

- Double-stage reverse osmosis equipment

- Pure water equipment

- Single-stage reverse osmosis equipment

- Medical purified water equipment

- Hospital pure water equipment

- Ultrapure water equipment

- Recycled water reuse equipment

- Commercial pure water machine

- About

- Case

- News

- Contact

Over the past 5 years, we have solved water problems for tens of thousands of enterprises

产品展示

products

- Sewage treatment equipment

- Laboratory ultrapure water machine

- Ultrapure water equipment

- EDI ultrapure water equipment

- Medical purified water equipment

- Hospital pure water equipment

- Pure water equipment

- Single-stage reverse osmosis equipment

- Double-stage reverse osmosis equipment

- Seawater desalination equipment

- Ultrafiltration equipment

- Container integrated water purification equipment

- Recycled water reuse equipment

- Commercial pure water machine

10T of recycled water reuse equipment, RO reverse osmosis system, industrial wastewater reuse device, industrial super Water filtration and purification equipment

This system adopts multi-stage filtration + membrane treatment (MBR/UF/RO) technology to treat domestic sewage, industrial wastewater, etc. into recyclable recycled water, with a water production of 10 tons/hour, and the water quality meets the standards for sewage recycling and utilization. It is suitable for greening, flushing, cooling circulation and other scenarios, helping enterprises save water and reduce emissions.

This system adopts multi-stage filtration + membrane treatment (MBR/UF/RO) technology to treat domestic sewage, industrial wastewater, etc. into recyclable recycled water, with a water production of 10 tons/hour, and the water quality meets the standards for sewage recycling and utilization. It is suitable for greening, flushing, cooling circulation and other scenarios, helping enterprises save water and reduce emissions.

10T of recycled water reuse equipment

Introduction to recycled water reuse system

Drinking water: Treat recycled water into drinking water standards and directly reuse it in daily life, that is, realize direct recycling of water resources. This treatment method is suitable for areas with extremely lack of water resources, but the investment is high and the process is complex.

Domestic water: Treat recycled water to non-guided drinking water standards, mainly used for water that does not come into direct contact with the human body, such as toilet flushing water, floor car cleaning water, greening water, fire fighting water, ordinary industrial water, etc. This is the usual recycled water treatment method.

Industrial water: Recycled water reuse technology can be used to retreat industrial wastewater that meets the discharge standards to achieve industrial recycling. Through softeners, RO, EDI/mixed beds and other equipment, it can achieve the standards of softened water, purified water, and ultra-pure water, so as to save capital and protect the environment.

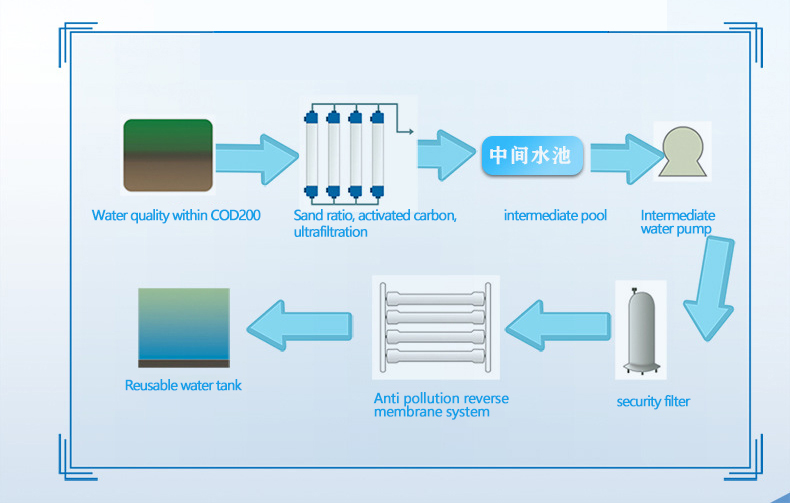

Common process flow chart

Main process

Physical treatment method: Membrane filtration method is suitable for situations where water quality changes are large and is used to reuse reclaimed water for industrial production water.

The characteristics of this process are: the device is compact, easy to operate, and less affected by load changes. The membrane filtration method is to use external forces to separate solvents, low molecular weight substances and inorganic ions in the separated solution pass through the filter membrane into the low pressure side from the high pressure side and discharge them as filtrate; while the polymer substances, colloidal particles and microorganisms in the solution are intercepted by the ultrafiltration membrane, and the dirty liquid is concentrated and discharged. Typical processes include: UF+RO(NF), MBR+RO(NF).

Physical and chemical method: It is suitable for situations where sewage water quality changes greatly, and is used to recycle recycled water for domestic miscellaneous water. Generally, the methods used include: sand filtration, activated carbon adsorption, flotation, coagulation precipitation, carbon softening, and ozone oxidation.

The biological treatment method is suitable for sewage with high organic content and is generally used to reuse recycled water for domestic miscellaneous water. Generally, biological treatment methods such as activated sludge method, contact oxidation method, and biological turntable are used. The above methods can be used alone or in combination, such as contact oxidation + biological filter, biological filter + activated carbon adsorption, turntable + sand filtration and other processes.

Compound process: that is, a process that combines biological treatment method, physical and chemical method, and membrane filter tank. This process is the most commonly used method for reuse of industrial wastewater from production water. Its typical processes include:

1) Biochemical treatment + sand filtration + UF + RO(NF):

2) Biochemical treatment + MBR + RO(NF);

3) Biochemical treatment + advanced oxidation + UF + RO(NF).

Application field

domestic sewage, industrial sewage, hospital sewage, car washing wastewater, automobile manufacturing, glass washing

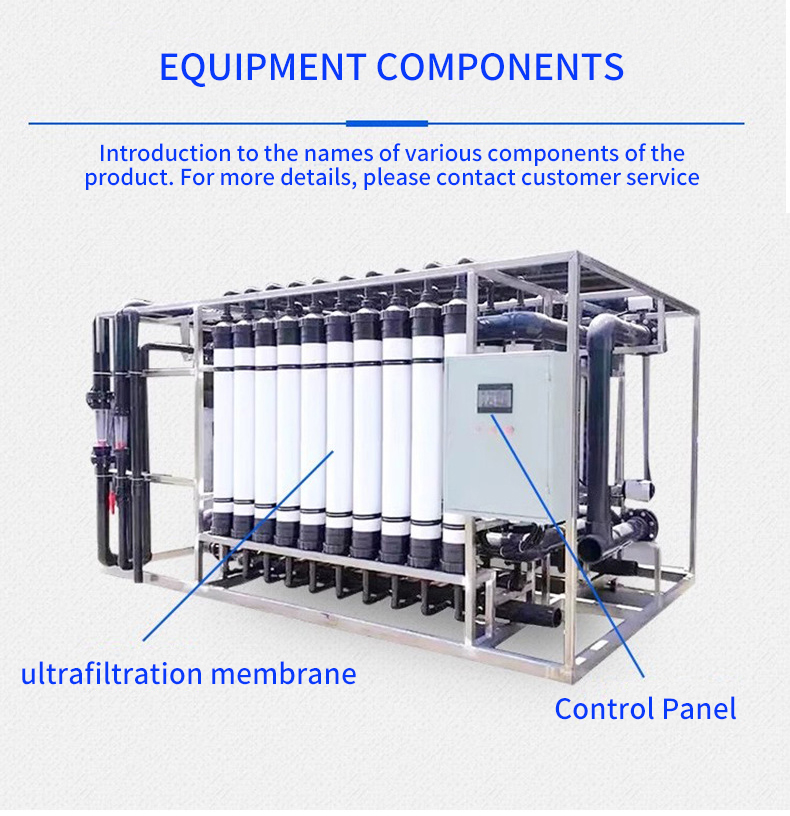

Product Information

| Device name | Recycled water reuse system |

| Equipment size | Customizable |

| Filtration principle | Ultrafiltration filtration |

| Cleaning method | Automatic backwashing |

| Main applications | Treatment of domestic drinking water; deep purification of tap water, well water and surface water; treatment of process water, food and drug water, clarification, separation, purification, and concentration of various materials; industrial wastewater sewage treatment, recycled water reuse, RO pretreatment |

| Main features | No phase change, low energy consumption, low operating cost, small footprint, simple layout, convenient capacity expansion, pure physical filtration without secondary pollution, high filtration accuracy, turbidity less than 0.1NTU, SDI less than 1, fully automatic operation can achieve unattended |

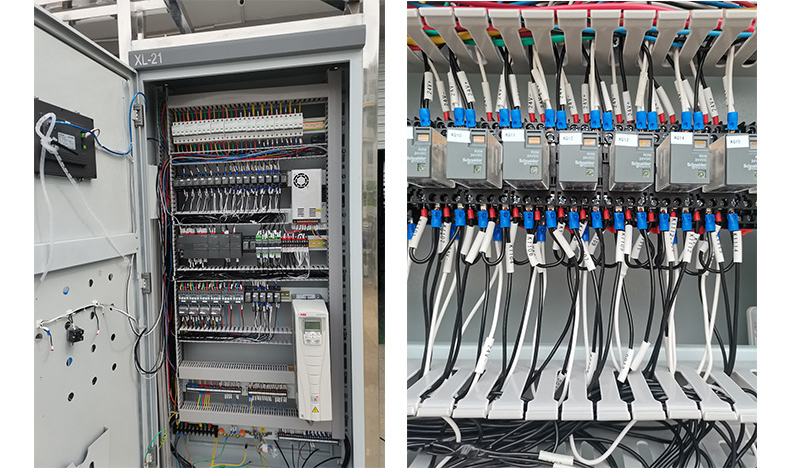

Electrical cabinet control system

The core heart part of the machine, the control cabinet uses a 24V transformer, and all control parts are safe voltage and operate in a fool. The working status is clear at a glance through indicator lights or touch screens. The overall operation is simple and easy to understand and easy to operate.

Recent Cases

what app

Address: No. 9655, Tingwei Highway, Jinshan Tinglin Industrial Zone, Shanghai

Mobile phone: +86 17717591248

WhatsApp: +852 5534 9894

Email: bosen7298@gmail.com

- Home

- Product

- Seawater desalination equipment

- EDI ultrapure water equipment

- Laboratory ultrapure water machine

- Ultrafiltration equipment

- Sewage treatment equipment

- Container integrated water purification equipment

- Double-stage reverse osmosis equipment

- Pure water equipment

- Single-stage reverse osmosis equipment

- Medical purified water equipment

- Hospital pure water equipment

- Ultrapure water equipment

- Recycled water reuse equipment

- Commercial pure water machine

- About

- Case

- News

- Contact